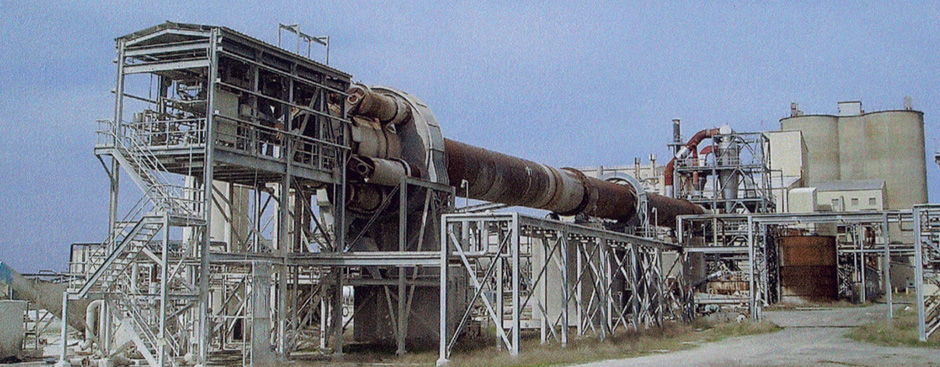

11' X 310' Fuller-FLS Rotary Kiln

This 11' X 310' Fuller-FLS Rotary Kiln has already been dismantled and is ready to ship. Formerly used for re-causticizing lime it has 4 support stations. It was new in 1998 and has been used for less than 1 year total.

Main Details:

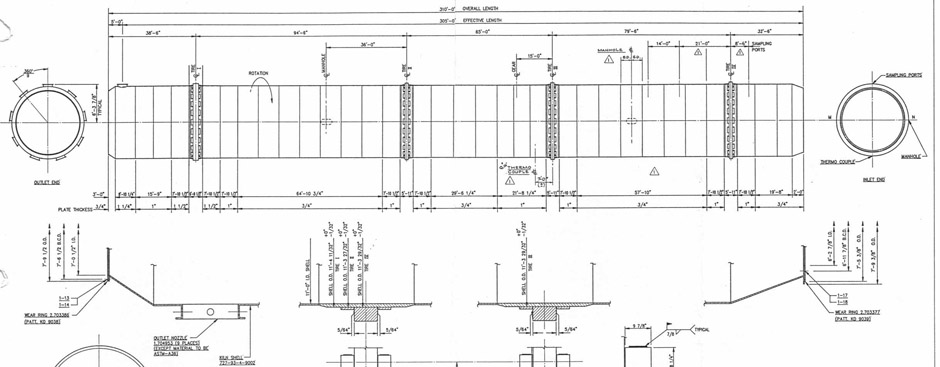

- One (1) Used 11' X 310' Fuller-F.L. Smidth Rotary Kiln

- • New in 1998 and USED 12 MONTHS TOTAL ONLY

- • Formerly used as a lime reburning (recausticizing) kiln

- • Kiln shell of ASTM Spec. A-36 mild steel plate, shell thickness:

- Tire section I: 2-1/4"

- Tire sections II, III, IV: 2"

- Intermediate section I: 1"

- Intermediate section II, II, IV: 1"

- Outlet to support I: 1"

- Support 1 to support II: 3/4"

- Support 2 to support III: 3/4"

- Support 3 to support IV: 3/4"

- Inlet and Outlet cones: 3/4"

- Cooler section: 1"

- • 4 sets of supporting mechanisms, each consisting of 1 tire, 2 rollers with shafts,

- 1 graphite lubricating block and holder, 4 bearings and 1 structural

- steel base. Each pier has a water cooling system for the support roller

- bearings, complete with tank and pump.

- • FLS support rollers with self aligning ball and socket type bearings. Rollers

- are made of high-grade cast steel, ASTM 148, Grade 120-95

- • Size of support roller I : 51-3/16" O.D. X 33-1/2" face, bearings

- 15-3/4" dia. X 22-1/2" long (FLS type 1958, 400mm dia.)

- • Size of support roller II, III, IV : 39-3/8" O.D. X 20-3/4" face,

- bearings 11" dia. X 15-3/4" long (FLS type 1958, 280mm dia.)

- • Size of tire I : 13'2" O.D. x 11'4-1/2" I.D., 29" face

- • Size of tire II, III, IV : 13'0-1/2" O.D. x 11'4" I.D., 17-1/4" face

- • 1 Thrust roller mechanism, 50" dia. X 6" face roller, structural

- steel base (on tire III)

- • Girth gear, 2-piece helical, 18-1/2" face, 212 teeth, mounted on

- 10 spring plates

- • Pinion gear, helical (19" face, 20T) with shaft, SKF 23144CC/C3/W33

- self-aligning roller bearing pillow blocks

- • All-weather gear guard with base and lubricating wheel

- • Falk 1200T10 coupling (pinion-gearbox)

- • Speed reducer:

- Santasalo Type 3C500N

- 312HP rating at 1180 RPM input

- Ratio 75.656:1

- Output speed 15.4 RPM, with couplings, guard and base

- • Kiln drive motor : 150HP 1180RPM 60Hz 480V 3 phase

- • Falk 1090T10 coupling (gearbox-drive motor)

- • Kiln operating speed with current drive configuration: 1.0-1.45 RPM

- • Kiln inching drive assembly:

- Marland Cecon CEUS 2M clutch with 2 Amerigear F202-1/2 couplings

- Hansen JKN53C right angle reducer, ratio 22.31:1

- Marland CEBMAG-5CW backstop with 2 Amerigear F202-1/2 couplings

- 20HP 1800RPM 60Hz 440V motor

- • Kiln drive base

- • Emergency drive generator station with 40HP natural gas engine

- (provides electricity to kiln inching drive motor in event of power failure)

- • CVS natural gas kiln burner, 95 MM btu/hr maximum, 76 MM btu/hr

- nominal, fuel consumption 95,000 SCFH natural gas

- • Burner carriage, rail mounted

- • Gas valve train

- • Burner primary air fan, 2400 SCFM, 30" W.G., 25HP motor

- • Approximate weights:

- Kiln Shell: 475,000 lbs.

- Tires: 111,000 lbs.

- Support Mechanisms: 137,000 lbs.

- Drive Mechanism: 66,000 lbs.

For a price offer and further details please inquire